MSC Software

-

MSC Simufact

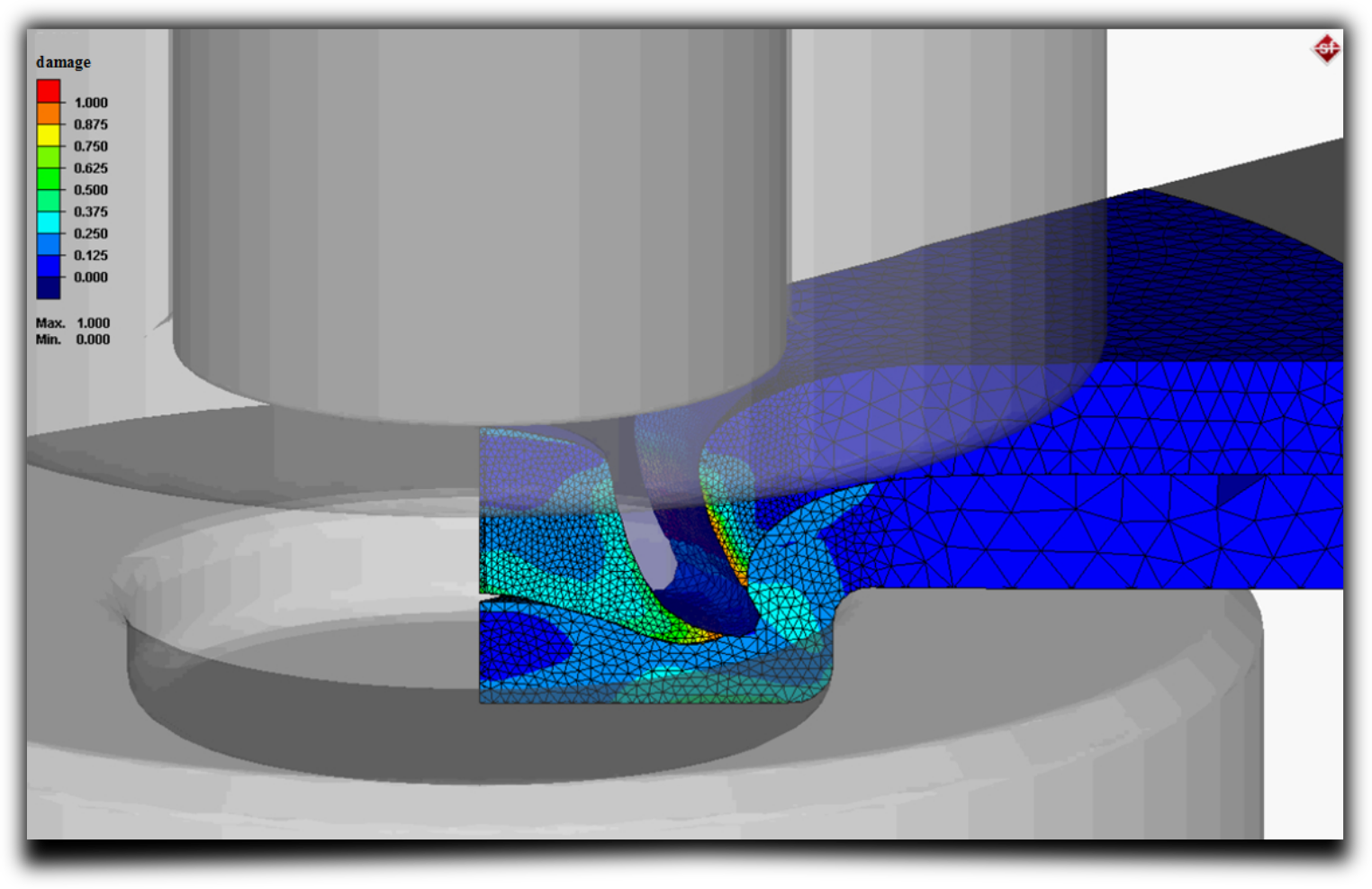

Simufact is a leading FEA based simulation solution for metal forming, welding and heat treatment. With the ability to simulate the entire manufacturing process chain, starting from blanking, shearing of wires or billets, to multi-stage forming, punching, trimming, and heat treatment followed by joining operations, welding and structural analysis, Simufact helps optimize the manufacturing processes, and reduce costs and time-to-market, while improving product quality.

-

Two product lines are available as part of the Simufact family

Simufact.forming covers the complete spectrum of forming technologies and guarantees a realistic portrayal of the processes with full 3D functionality and 3D representation of all the tools and parts. Accurate simulations are possible by capturing the key aspects that affect the processes, which include:• The kinematics of the machine

• Nonlinear material behavior of the workpiece including

plasticity, rate dependency and temperature effects

• Friction and contact between tools and forming parts

• Self-contact of forming parts to predict folds, and

• Thermodynamics of the process: initial heating conditions,

temperature increase due to forming energy and friction,

and heat transfer between tools, workpiece and

environment. -

Two product lines are available as part of the Simufact family

Multiple modules are available to address the processes of interest to you. The core module of Forming Hub includes the key functionality necessary for the operating and handling ability of the simulation software (GUI, solver, material database etc.), along with capabilities to perform cold forming and hot forging simulations. Users can choose from any of the others listed below to augment their simulation capabilities.• Sheet metal forming

Additional modules are available to help with die stress analysis and microstructure calculations, faster performance, CAD import, customization, and access to material databases.

• Rolling

• Ring rolling

• Open die forging

• Heat treatment

• Mechanical joining

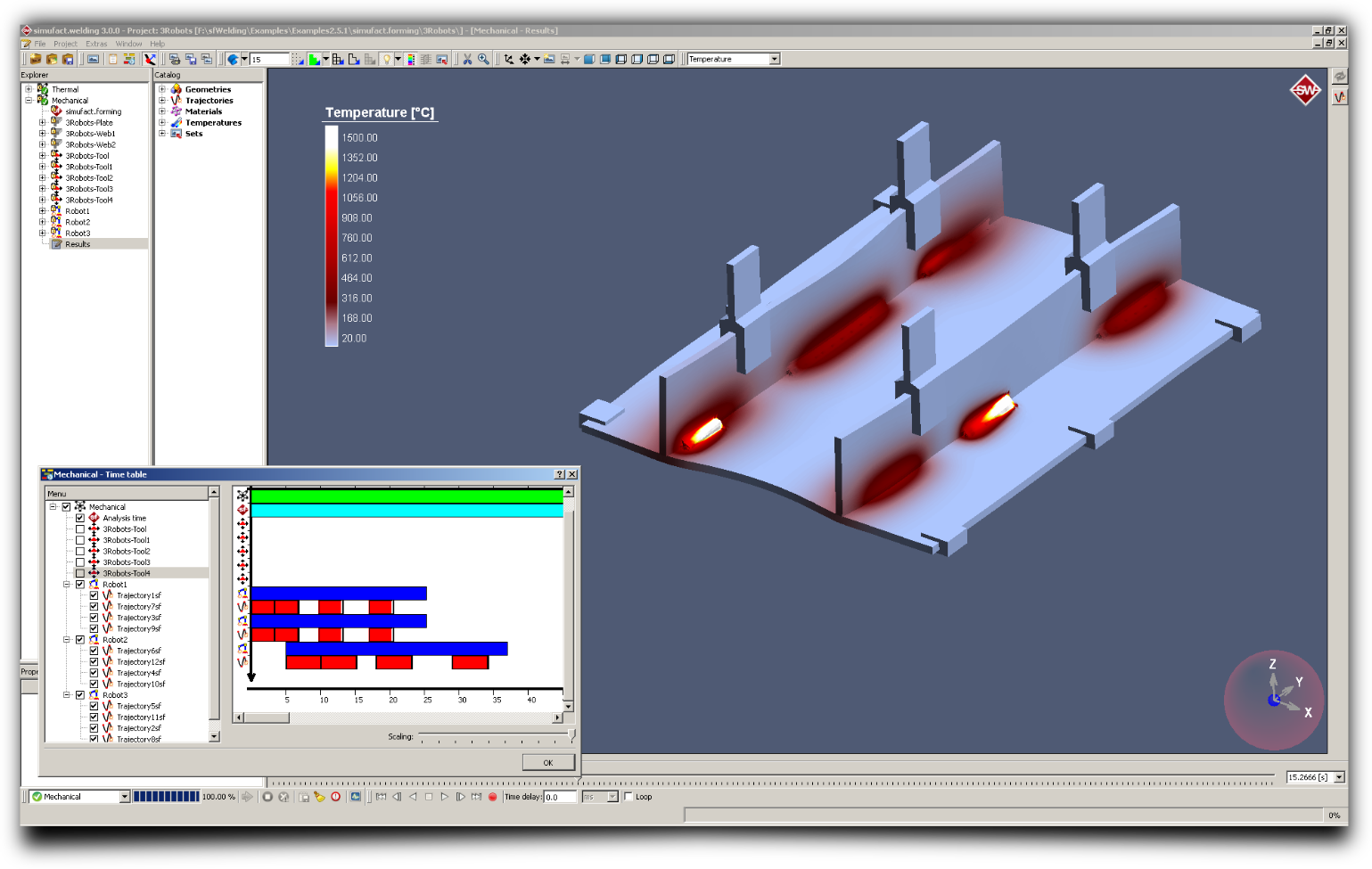

Simufact.welding helps simulate complex welding processes that may involve multiple welding sequences and predicts distortions of the components, while considering phase transformations occurring during the process. With Simufact.welding, users gain insight into the properties of the weld seam, and welding defects such as hot cracks, helping them to address problems prior to putting the process into use.

By coupling Simufact.welding with Simufact.forming, users can simulate a combination of various process chains with upstream and downstream welding processes. Easy data transfer allows not only consideration of the forming history, but also strength analysis of simulated welded seams.